Illustrate the whole process to see how raw materials are transformed into apparel step by step!

A few years ago, when we want a new apparel in our daily life, we only need to go to the mall to choose from a wide range of styles. And now, through online shopping, we can get the new clothes delivered to our door without leaving the house. Do you guys know how a piece of cloth is produced? What exactly did the blossoming white cotton go through to become such beautiful and fashionable clothes? Let's follow below to see the whole process of a piece of clothing production!

1.Blossoming white cotton as below

2.Cotton Wadding after processing to remove the seeds

3.Cotton cleaning process: impurity removal, cotton blending and rolling

4.Carding process: decompose the cotton lump into a single fiber to improve the straight and parallel state of the fiber

5.Rolling process: merging and drafting to improve the straightness and equality of the fibers into the small rolls of specified length and weight.

6.Combing process: further remove neps, impurities and fiber defects in the fiber, eliminate short fibers below a certain length, improve the length uniformity and straightness of the fiber, and draw the sliver to a certain thickness.

7.Drawing process: drawing and thin-stretching the fiber, then mixing and forming into sliver.

8.Roving process: The sliver is evenly drafted, elongated and thinned, and the drafted sliver is properly twisted to make the yarn have a certain strength.

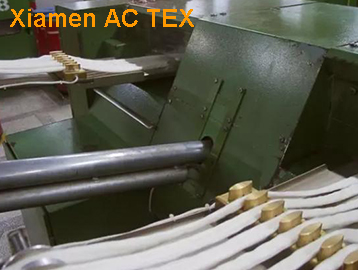

9.Spinning process: drafting, twisting, winding and finally forming.

10.Winding process: winding and forming, winding the bobbin (thread) into a bobbin with large capacity, well-formed and certain density, and remove some defects and impurities on the yarn to improve the quality of the yarn.

11.Twisting process: Twisting, using two or more single yarns, after merging, twisting to make a strand with high strength and good structure, and then winding the twisted strand on a bobbin which the pipeline is of a certain size and shape to be convenient for handling and subsequent processing.

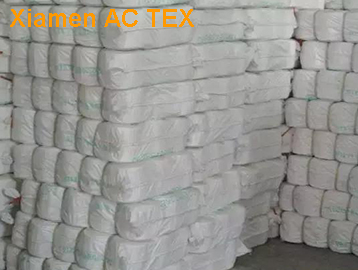

12.Yarn-shaking process: The yarn (thread) wound on the package is shaken into a hank (thread) according to the specified length, which is convenient for packaging, transportation and process processing.

13.Packaging process like below

1.Warping: a one-step process of converting the original yarn (package yarn) into a warp yarn (BEAM) through the creel, which is divided into three types: original yarn warping, colored yarn finishing and partial warping.

2.Yarn Sizing: After sizing and warping, BEAM or dyed BEAM (warp beam) is hung on the creel of the sizing machine, passing through the sizing liquid in the sizing tank → cylinder for drying → creel dividing and Layering→Integrate into woven or knitting BEAM.

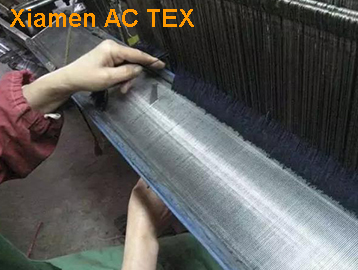

3. Drawing-in: The sizing yarn passes through three accessory parts, such as warp drop, heald and steel reed, to facilitate the weaving or knitting of warp drop: one of the induction devices to prevent warp yarn from breaking, and the induction can be completed with the warp bar.

4. Weaving or knitting: the shaft yarn that has been drawn through is hung on the loom through the load of the locomotive to do weaving or knitting

5. Finished grey cloth

6. Dyeing into finished fabric

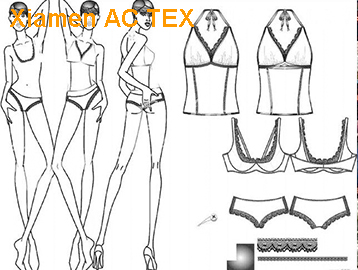

1.Clothing design by clothing designer

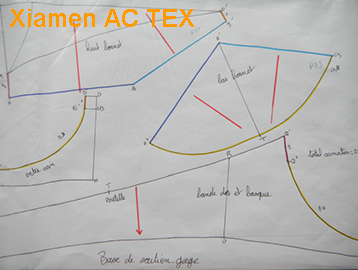

2. Pattern design: Enlarge or reduce the drawing of the standard pattern, which is called "pattern grading".

3. Production preparation: necessary inspection and testing of fabrics, accessories, sewing threads and other materials required for production, pre-shrinking and finishing of materials, sewing and processing of samples etc.

4. Cutting process: cutting fabrics, linings and other materials into garment pieces according to patterns

5. Sewing process: each piece of clothing is sewing together to combine into apparel.

6. Ironing process: After the garment with private label is made, it is ironed to achieve the ideal shape and make it beautiful.

7. Custom made garment quality control: Research the quality problems that may arise during the processing of products and do necessary quality inspection based on AQL standard.

8. Post-processing: Post-processing includes packaging, storage and transportation, and is the last process in the entire apparel manufacturing process.

Categories

New Blog

Copyright © 2026 XIAMEN AC TEX INDUSTRY&TRADE CO.,LTD.. All Rights Reserved.

IPv6 network supported